Understanding Solvent Based Ink

In the vibrant world of printing, solvent based ink stands out as a preferred choice for many professionals. Known for its durability and rich color saturation, solvent based ink is ideal for outdoor applications where resistance to weather elements is crucial. Unlike water-based inks, solvent based inks use organic solvents for dispersion, leading to superior adhesion on various substrates, such as vinyl and banners. This makes them especially popular in signage and graphic printing. Furthermore, the versatility of solvent based ink allows it to blend seamlessly with coatings, enhancing the longevity of the printed material. For artists and businesses seeking high-quality outputs that can withstand the test of time, the richness and vibrancy of solvent based ink is unparalleled, promising visual appeal that captures attention.

The Role of Solvent Based Ink Manufacturers

When searching for quality printing solutions, the role of solvent based ink manufacturers cannot be understated. These manufacturers are dedicated to producing inks that not only meet safety standards but also offer a variety of options to cater to diverse printing needs. Whether it’s eco-solvent inks that minimize environmental impact while providing outstanding print quality or traditional solvent inks suitable for heavy-duty applications, reliable manufacturers are crucial partners in the printing industry. They are equipped with advanced technology and understanding of the latest trends. This allows them to innovate continuously, ensuring that clients have access to products that help them achieve their creative and commercial goals. Quality assurance in the printing process is paramount, and through strong partnerships with solvent based ink manufacturers, businesses gain access to inks that elevate their final products, ensuring both customer satisfaction and brand loyalty.

Diving into Solvent Based Ink Formulation

The science behind solvent based ink formulation is a key aspect that distinguishes high-quality inks in the industry. Formulating solvent based inks involves a delicate balance of pigments, solvents, and additives to ensure the final product performs exceptionally well. High-quality pigments provide vibrant colors, while appropriate solvents ensure proper flow and drying time. Additionally, additives can improve attributes such as smudge resistance, UV stability, and even flexibility, depending on the intended use. With the increasing demand for sustainable products, manufacturers are also focusing on formulations that meet environmental regulations without compromising on quality. For printing professionals, understanding the formulation process can lead to better choices in inks that suit specific applications, helping them achieve the desired result effectively.

Conclusion: Trust in Premier Manufacturers

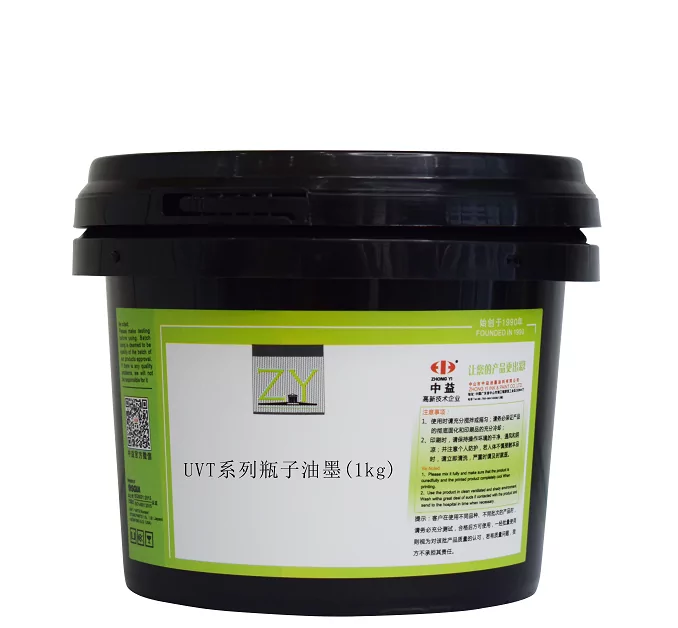

In conclusion, the glory of solvent based ink lies in its exceptional qualities alongside the expertise of solvent based ink manufacturers and formulation processes. For those seeking a reliable partner in the printing industry, Zhongyiink emerges as a leading choice, offering an array of high-quality inks designed to meet diverse printing demands. With a commitment to innovation, sustainability, and customer satisfaction, Zhongyiink provides not just products, but solutions that empower creatives and businesses alike to bring their visions to life.