Are you interested in learning about lsr molds and their applications? Look no further! In this guide, I will provide you with valuable insights into the world of lsr molds and how they are making a significant impact in California’s manufacturing industry.

The Versatility of LSR Molds

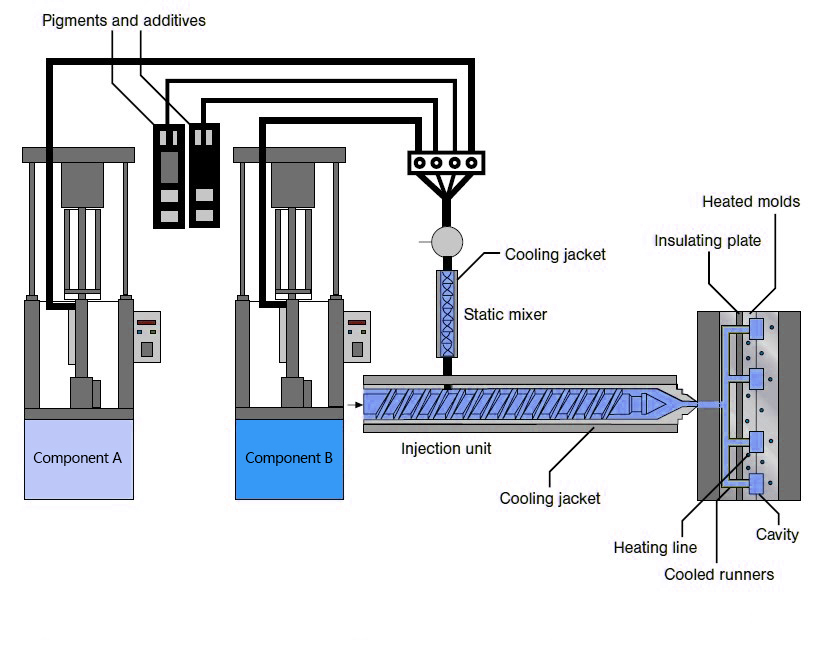

LSR (Liquid Silicone Rubber) molds have revolutionized the manufacturing process by offering unparalleled versatility. These molds are capable of producing intricate designs with precision and consistency, making them ideal for various industries such as automotive, medical devices, electronics, and more. With their ability to withstand extreme temperatures and resist chemicals, LSR molds ensure durability and reliability.

JVTECH: A Leading Provider of LSR Molds

When it comes to high-quality LSR molds in California, JVTECH is a name that stands out. With years of experience in the industry, JVTECH has established itself as a trusted provider known for its cutting-edge technology and exceptional customer service. Their team of experts works closely with clients to understand their specific requirements and deliver customized solutions that meet or exceed expectations.

LSR Brand Consulting: Enhancing Your Manufacturing Process

In addition to providing top-notch LSR molds, JVTECH also offers comprehensive brand consulting services through its subsidiary company – lsr brand consulting. This division focuses on helping businesses optimize their manufacturing processes by leveraging advanced technologies like automation systems, data analytics tools, and supply chain management strategies. By partnering with lsr brand consulting, companies can streamline operations while maximizing productivity and profitability.

In Conclusion

The utilization of LSR molds has become increasingly prevalent across various industries in California due to their unmatched versatility and durability. Companies like JVTECH and its subsidiary, LSR Brand Consulting, play a crucial role in providing high-quality molds and assisting businesses in optimizing their manufacturing processes. By embracing the potential of LSR molds, companies can stay ahead of the competition and achieve long-term success.